Laser Shaft Alignment

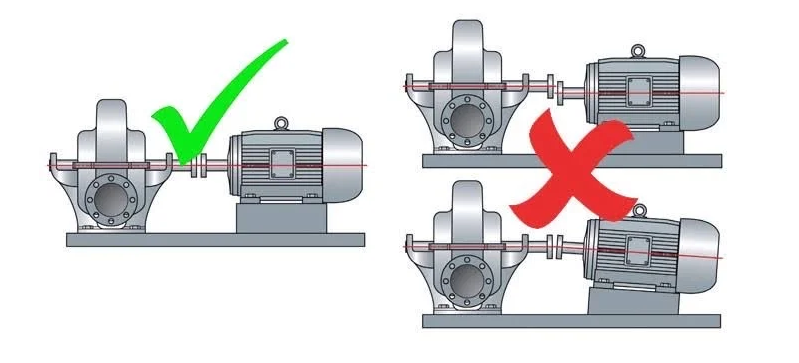

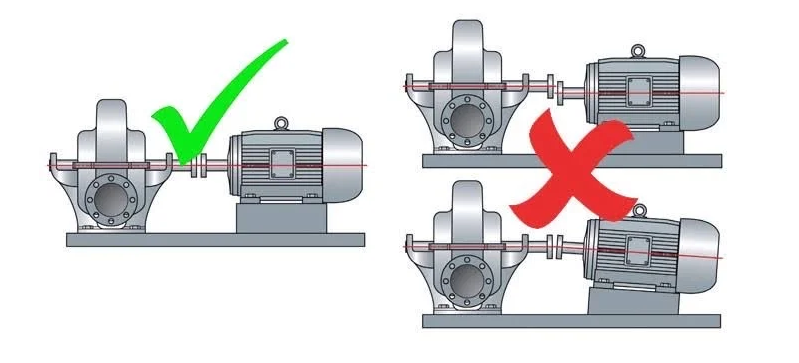

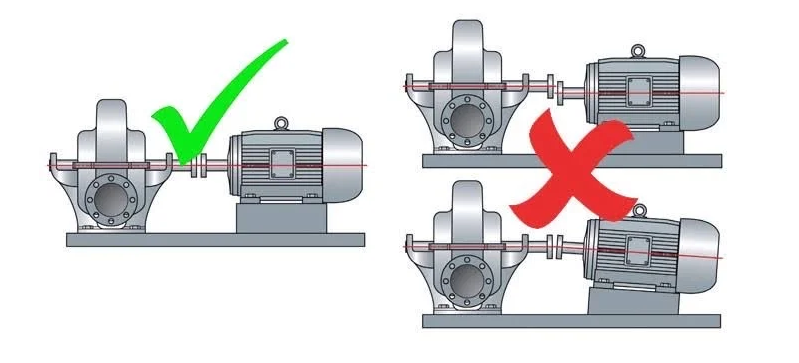

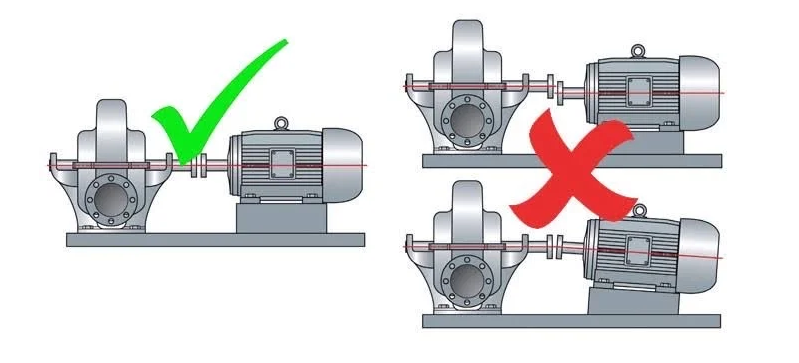

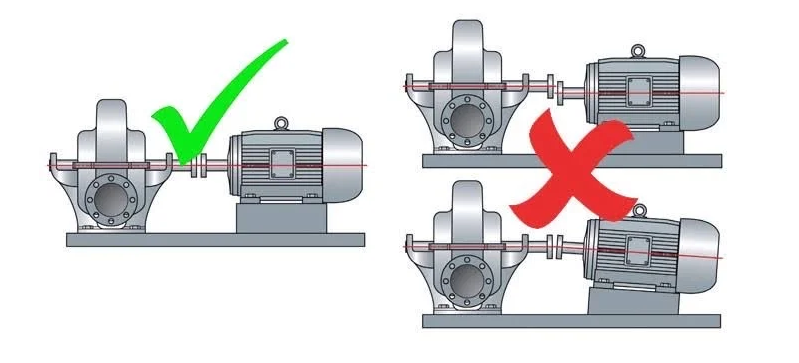

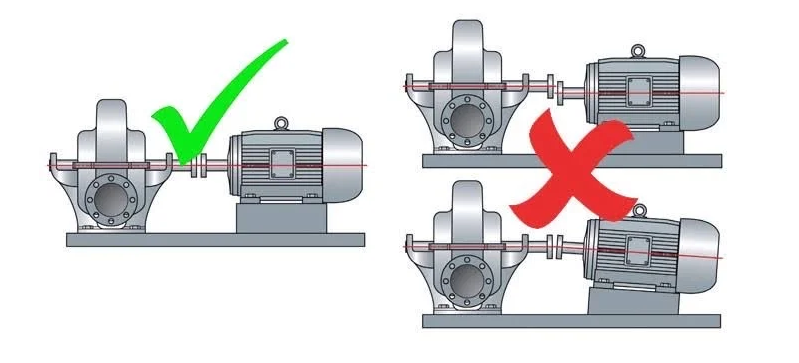

Shaft alignment is the positioning of the rotational center of two or more shafts such that they are co-linear when the machines are under normal operating conditions.

Accurate alignment of equipment helps to solve machine problems such as decreased running speed, bearing and coupling failures, abnormal vibration, roll cover damage, and improper nip impression.

Types of Misalignment?

- Parallel or Offset Misalignment

- Angular Misalignment.

- Combined Misalignment

Industrial Laser Shaft Alignment services provider

Bilvam India is Industrial Laser Shaft Alignment services provider in India & abroad. In experienced hands lasers are much quicker and will result in a more accurate alignment. With a range of global customer locations and a full team of engineers, technicians, and support staff, we are able to accurately provide your alignment services in the time frame you need.

Benefits of Shaft Alignment

Reduced Energy Consumption

Reduced Incidence of Repairs

Longer Machine Life

Benefits of Shaft Alignment

1. Reduced Energy Consumption

Significant power savings can be made through accurate alignment. Precise alignment eliminates reaction forces and reduces energy consumption by up to 10%.

2. Reduced Incidence of Repairs

Mechanical seal repairs decline by up to 65% when precision alignment is carried out on a regular basis. The rate of repairs declines by up to 30% when precision laser alignment becomes an integral part of the pump repair schedule. Maintenance costs are also reduced through lower parts expense and inventory levels

3. Longer Machine Life

Relation between offset and bearing life cycle: The smaller the offset misalignment, the greater the expected bearing life cycle.

4. Low machine vibration

Protects the assets and increases product quality as the vibrations are reduced to very low levels

5. Mean Time Between Failure

Extends the machine availability as the mean time between failure increases

6. Manpower cost reduction

Laser shaft alignment Increase in time savings and decrease in consumption of manpower for carrying out alignment.

Alignment Services are done on

- Motor Driven Pump

- Direct Coupled Fan & Blower

- Alternators

- Gear Boxes

- Compressors

- Cooling Tower Assembly

- Turbines

- Shaft of ships

- Conveyors

- Crushers & Mixers

- Spindles and any type of drive and Machine Assembly