In-situ Dynamic Balancing

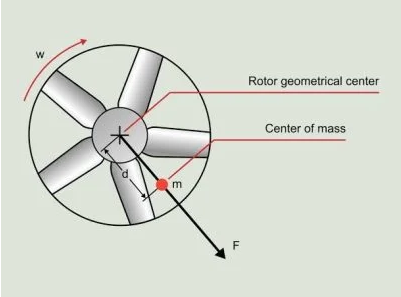

What is Unbalance?

Uneven distribution of mass around an axis of rotation. A rotating mass, or rotor, is said to be out of balance when its center of mass (inertia axis) is out of alignment with the center of rotation (geometric axis).

What is Balancing?

The process of minimizing vibration, noise and bearing wear of rotating bodies by adding, removing and shifting the correction weight on rotor/fan. Unbalance problems will be rectified In-situ (On site) by our skilled and experienced ISO/ASNT Cat-II & III certified professionals to achieve maximum Machine Availability, Production & Profits to our valuable customers

In-situ Dynamic Balancing

What is Balancing?

In-situ dynamic balancing refers to the process of balancing rotating machinery directly at its operational site (in-situ), without needing to dismantle or transport the equipment to a balancing facility. This is especially useful for large, installed machines like turbines, compressors, or fans, where disassembly is impractical. It helps minimize vibration, prevent damage, and increase the lifespan of the machine.

In-situ Dynamic Balancing

What is Balancing?

In-situ dynamic balancing refers to the process of balancing rotating machinery directly at its operational site (in-situ), without needing to dismantle or transport the equipment to a balancing facility. This is especially useful for large, installed machines like turbines, compressors, or fans, where disassembly is impractical. It helps minimize vibration, prevent damage, and increase the lifespan of the machine.

Main Advantage

The main advantage of balance “in situ” is the cost savings in the removal, transport, and assembly bench execution large rotors or weights, or installed in inaccessible locations requiring cranes or other hazardous operations.

Benefits of In-situ Dynamic Balancing

Balancing without removal of rotor from assembly

Short time

Minimize vibration and Noise

Increase machine life span and productivity

Increase bearing life, Increase product quality

Increase machine life & Productivity

Minimize operator fatigue and annoyance

Minimize maintenance cost

Minimize structure stress

Bilvam India services include Onsite & Workshop balancing

- Turbine

- Generators

- Fans and blowers

- Pump impellers

- Electrical motor rotors

- Process rolls

- Air Pulleys and sheaves

- Compressor components

- Gears

- Crankshafts

- Bearing spindle assemblies

- Centrifuges

- Printing drums

- High-speed tooling

- Cutting tools