Natural Frequency & Resonance Analysis

Resonance is a very common cause of excessive machine vibration. It is the result of an external force vibrating at the same frequency as the natural frequency of a system.

If equipment is operating in a state of resonance, the vibration levels will be amplified significantly, which can cause catastrophic failure of machine and plant downtime. It is, therefore, important that the running speed of equipment be out of the resonance range.

Bilvam India's expertise and techniques can be used to identify and/or confirm a high vibration level caused by a resonance frequency for sudden failure prevention.

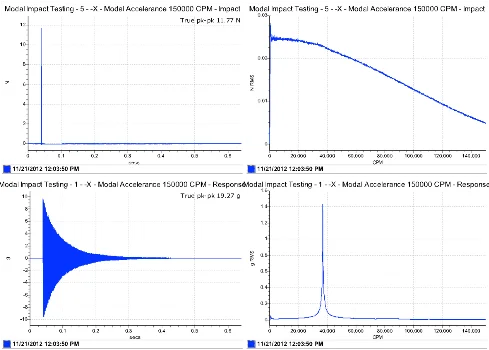

Impect Test

One of the most commonly used methods for measuring a system’s natural frequency is to strike it with a mass and measure the machine response. Test can be performed with the help of mallet hammer or instrumented hammer with acceleration spectrum with two channel analyzer to excite the system.

Using this technique you can effectively measure the force instrumented to the system by the instrumented hammer and the response at different frequencies .When the phase shifts by 90 degrees, the frequency at which it occurs is a natural frequency.

The advantage in using this method is that it allows you to monitor phase shifts and coherence with this information ,you can create operating deflection shapes to visualize the vibration body.

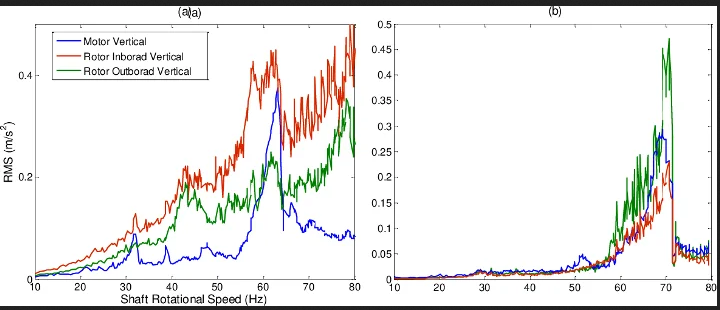

Coast Down Peak Hold

Another method used to monitor the vibration level using a peak hold function,while starting & shuffling down the equipment,as performed normally.

The vibration level should drop at a steady rate.if the vibration levels start rising at any time while the equipment is being shut down,the speed at which the amplitudes increase is a possible natural frequency.

Coast Down Peak Phase:

By installing a photo tack and a piece of reflective tape on the roating shaft of the equipment,you can monitor the vibration and its phase.

This will allow you to see the amplitude and phase shift at all running speeds of the equipment.if there is no response excited by the turning speed,the vibration levels should drop at a steady rate.

If the vibration peaks at a certain speed and the phases shifts by 180 degrees,this indicates a natural frequency of the equipment of structure the actual natural fgrequency is the frequency is the frequency situated in the middle of the phase shift(90 degrees)